New refractory coatings to reduce cleaning effort and increase life time

Wherever metals are melted and further processed, operators of furnace plants and slag management employees are working against the resulting contamination of the respective refractory materials and metallic surfaces. In some cases, a considerable amount of time is required to remove the solidified material from the respective areas. In addition, any damage that may occur must often be repaired in a time-consuming process.

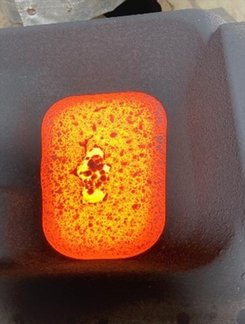

Hüttenes-Albertus was given the task by a development partner to formulate a coating for various applications when handling melts and slags. The resulting products enable customers to use a protective layer which is abrasion-resistant and thermally stable after complete drying. This posisitive effect is created by influencing the wetting angle so that adhesion can be prevented. After dilution of the pasty raw products, the respective coatings are applied by spraying, brushing or dipping and effectively counteract the accumulation of melt residues on metallic surfaces, ladles, troughs or other areas. Grippers, ingot molds and other tools can also be coated in a simple way.

Contact

For further information about our new product line please feel free to contact us.

Hüttenes-Albertus Chemische Werke GmbH // E-Mail pm.germany@ha-group.com

Author: Martin Weith, HA Productmanager Coatings