How are suppliers strategically dealing with the raw material crisis?

In the current BDG report, Thomas Pfeiffer, Member of the Executive Board, Vice President Global Sourcing HA Group, explains how HA is dealing with the current bottlenecks on the raw materials market, which particular strategy makes it possible to remain able to deliver even in times of crisis.

Excerpt from the article writen by Thomas Pfeiffer

Strongly increased raw material prices due to extreme demand, among other things, as well as supply bottlenecks worldwide are currently posing immense challenges to companies and suppliers in the foundry industry and will probably continue to do so. There is no light at the end of the tunnel in sight.

As in 2020, 2021 was significantly impacted by the effects of the Corona crisis. In Q3 2021, an unprecedented combination of events was added to the already tense situation and continues to do so:

- Highly volatile demand makes planning difficult.

- There is a shortage of personnel at suppliers and logistics partners.

- Special events such as the UK leaving the EU or the blockade of the Suez Canal further exacerbate the situation.

- The force majeure reports are multiplying.

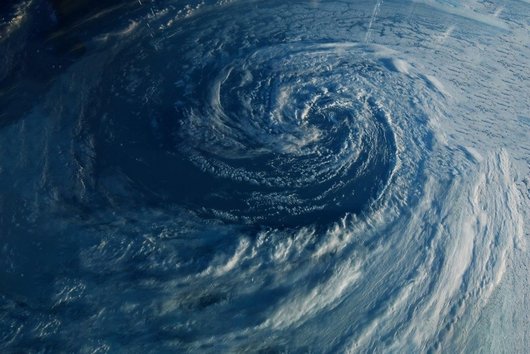

Companies face single or multiple challenges of this kind every now and then, but the fact that all of these events and effects occur simultaneously worldwide has never happened before. Such a "perfect storm" is unprecedented and there is no all-clear for 2022 either.

The effects of the chip shortage continue, the energy cost changes need to be assessed, and the consistent measures in China to reduce energy and emissions are becoming increasingly visible. Now more than ever, the right strategy for the crisis is decisive.

The key: A global network

The purchasing network of the global HA companies communicates regularly via digital media so that product market information can be exchanged transparently on an international basis.

With knowledge of the processes and changes in the various countries, the HA companies worldwide are able to react quickly even in times of bottlenecks and to help each other immediately, thus remaining able to deliver. HA Purchasing works closely networked, worldwide and along the complete process chain - this enables us to continue to deliver reliably.

The role of China

The procurement market of China is an indispensable core element of the procurement markets of all industries - whether as a direct supplier or as a supplier of our own suppliers. In order to be able to plan better and be prepared for anything, HA incorporates the plans of the Chinese government into its own strategies. The motto is 'hope for the best and plan for the worst'.

HA's strategy is to have supply chains from at least 2 continents. But that alone will not be enough given the current and upcoming situation. At the same time, it is always important to communicate closely with customers to have alternative solutions freetested as a precaution.

Even and especially in times when a face-to-face meeting is not possible, transparent communication plays a key role. HA's purchasing department regularly communicates digitally and directly with its own suppliers - in China and worldwide. Intercultural communication and understanding the situation of the different stakeholders is therefore one of the core competencies of a good purchaser.

The issues of the future

But the raw materials situation in China is not the only factor of uncertainty for today and tomorrow. In addition to the standard tasks of purchasing, the core topics of the future are: resilience, sustainability, and digitalization & processes. HA has defined each of the three topics in more detail for the international teams and derived pragmatic principles of action from them to serve as a guideline.

Read more in the article Challenge - Global Sourcing in Times of "Perfect Storms" by Thomas Pfeiffer, Vice President Global Sourcing HA Group.

bdgreport 3/21 Rohstoffe pages 21-25

https://www.guss.de/fileadmin/user_upload/bdg-reporte/03_21_bdg_report.pdf