HA x Laempe: Mega sand casting in automotive engineering

The following technical article is based on the collaboration between Hüttenes-Albertus and Laempe, which was presented at the ‘New Manufacturing World 2024’ and the ‘Formstoff-Forum 2025’.

From concept to component: the potential of sand casting in bodywork innovation

The automotive industry has been undergoing a substantial transformation for several years, characterised in particular by diversification in the powertrain. This is accompanied by an ever-increasing demand for weight reduction, which has led to a significant increase in the use of aluminium castings in car body construction. This rapid development is resulting in increasingly complex and larger structural components made from functionally integrated castings.

The technology known as MEGA or GIGA casting enables the production of extremely large components using die casting.

This high-performance manufacturing process for structural components has established itself in recent years and has developed into an interesting alternative to the previous method of car body construction using sheet steel. Nevertheless, it also presents significant challenges.

These include high investment costs, long set-up times and mould life, limited component design and corresponding repair and insurance issues.

Sand casting offers an alternative, efficient and technologically advantageous process. This process offers significant advantages, especially for medium-sized series. A joint project between foundry chemistry specialist Hüttenes-Albertus (HA Group) and Laempe, the expert in machine technology for core production, shows that new thinking and fresh approaches are also possible in this process.

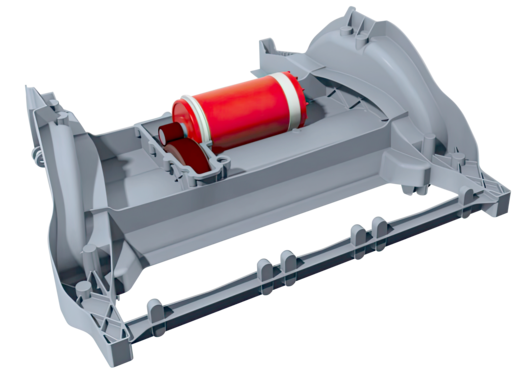

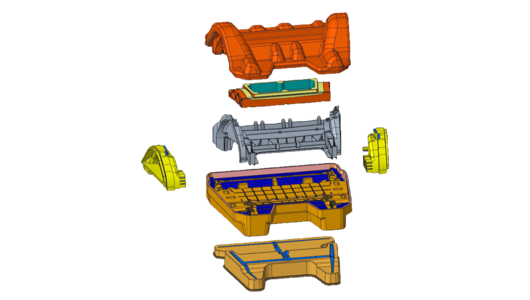

The study includes a concept for manufacturing a rear frame for a luxury vehicle using a low-pressure core package casting process (Figure 1 and 2).

It also provides an economic and ecological comparison with the die casting process. The results indicate that sand casting can be a valid alternative to die casting, especially with increasing design complexity and flexibility in the integration of functionalities and component size.

Manufacture of sand moulded parts using the core shooting process

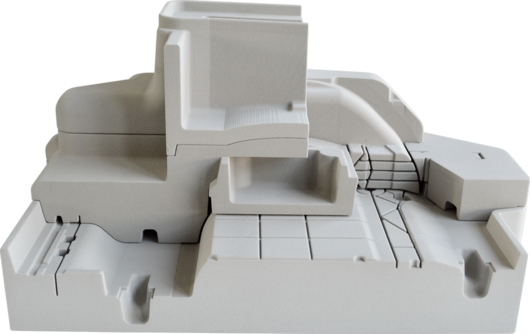

The sand moulds are produced using the core shooting process, optionally also by 3D sand printing. Quartz sand is typically used as the standard moulding material. The use of special moulding materials and binder systems to achieve specific properties of the cast parts is easily possible. The proven core shooting process ensures high dimensional accuracy and stability of the castings.

In addition, internal cores can be used to precisely reproduce undercuts and any complex cavities (Figure 3).

In the foundries, moulds and cores are assembled automatically by handling robots, ensuring high process reliability and efficiency. The transport and storage route of the mould packages to the casting plant is also automated, ensuring continuous and economical production.

Another advantage of the core shooting process is the flexibility of the production process. Tool changes can be made during the cycle and prototypes can be produced directly in series casting.

The use of additive manufacturing for core and mould production enables additional flexibility and exceptional design freedom, as there are no tool-bound restrictions in 3D printing (Figure 4).

The use of lost sand cores enables complex geometries with hollow structures and undercuts that cannot be produced in die casting. This also allows innovative concepts such as pack-to-open-body (cell-to-pack) solutions to be realised.

During casting, the mould packages are transported on rotating transport pallets with integrated permanent mould parts via roller conveyors to low-pressure casting machines. Pressure-assisted laminar mould filling is achieved via one or more riser pipes. The low-pressure casting process offers an advantage in terms of material characteristics compared to die casting due to directional solidification, as well as further technological incentives for variations in sands, binders and coatings.

Cost-effectiveness and stable processes

After process maturity, the concept part was subjected to a cost benchmark and evaluated using a cost analysis. The basis was a production of 250,000 pieces per year over a 7-year period.

The investment costs in the plant technology turned out to be about 30% lower than in GIGA casting. The manufacturing costs per part are comparable to GIGA die casting. For smaller series, the sand casting process offers significant cost advantages over die casting due to significantly lower tooling costs.

The material properties and wall thicknesses of the components are also at a similar level. High-quality cast parts can be produced through laminar mold filling and directed solidification. Die-casting challenges such as pull or adhesion points are avoided.

Advantages at a glance

MEGA sand casting is not only technologically but also economically attractive:

- Core shooting machines available in sufficient sizes: The technology is market-ready and can be used for large-area components.

- Proven core package process: Foundries are already familiar with the processes.

- Existing infrastructure: Much of the peripheral and manufacturing equipment is already in place.

- Tool-free production through 3D sand printing: Individual parts and small series can be produced flexibly and almost cost-neutrally.

- Realisation of special contours: Additive manufacturing allows geometries to be realised that would no longer be possible with conventional tools.

- Automated manufacturing processes: The use of robots and logistics systems ensures consistent quality with low personnel dependency.

The future knows no limits

The transformation in automotive casting presents new challenges for companies in the foundry industry, to which we must respond with innovative solutions. Ecological mobility requires lightweight construction and efficiency to minimise CO₂ emissions and make optimum use of resources. At the same time, the principle of "form follows function" demands maximum design freedom, which is often not achievable with permanent mould-bound die casting processes.

Advancing digitalisation and the development of software-defined vehicles (SDVs) are placing new demands on structural components. Integral components play a decisive role in enabling functional and weight-efficient design. New vehicle concepts such as open-to-pack architectures and advanced battery cells also require flexible manufacturing technology that can adapt to changing market requirements.

Another decisive factor is the use of artificial intelligence, which can accelerate technological developments and significantly shorten development times. Companies that have a high degree of production flexibility and can respond quickly to new market requirements will secure a competitive advantage in the long term. At the same time, the qualification and promotion of skilled workers is becoming increasingly important. Only with specialised and well-trained employees can companies maintain their innovative strength and create attractive, future-proof jobs.

Conclusion

The joint project by HA and Laempe clearly demonstrates the enormous potential of MEGA sand casting for automotive lightweight construction. Foundries not only gain an economical alternative to GIGA casting through this process but also a new business perspective. Through innovative technologies and collaborative partnerships, HA and Laempe support the industry in developing sustainable and flexible solutions.

The future of vehicle construction is characterized by new materials, production methods, and digitalization – with MEGA sand casting, a decisive step towards efficient and flexible manufacturing could be taken.