HA Special Sands

The term “special sand” covers all industrial minerals (except quartz sand) commonly used in foundries as moulding material for the manufacture of cores and moulds/dies.

Special sands include natural mineral sands, sintering and melting products produced in granular form or turned into granular form by breaking, grinding and grading processes, or inorganic mineral sands produced by other physical-chemical methods.

Special sands are different from quartz sand, particularly as regards their significantly lower thermal expansion behaviour within the temperature range of 20 – 600°C, their heat conductivity, refractoriness, and other physical characteristics.

Strengths of HA special sands

Special sands are used instead of quartz sand for coremaking and mouldmaking because they are characterized by better physical-chemical properties.

In consideration of the casting properties to be achieved, the individual advantages of a special sand can be used to:

avoid sand expansion defects, especially finning/veining

avoid the addition of gas-forming ingredients

reduce the core weight

avoid metal penetration

- increase the flowability of the sand

avoid a mould-metal interface reaction

control the formation of microstructure

produce thin-walled castings

Special sands for all requirements

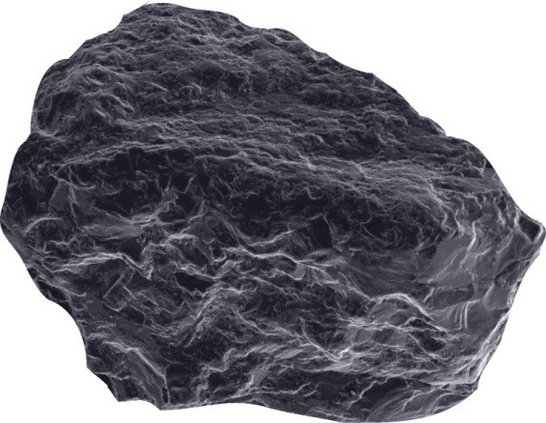

Kerphalite

The strengths of Kerphalite

Suitable for all casting types

Low coefficient of linear expansion

Can be used in the following processes: PUR-Cold-Box, SO2-Cold-Box and shell moulding, cold resin, resole-CO2 /MF, resol/ester, bentonite

- Ideally suited for high thermal stress

Characteristics

Natural, processed mineral = Andalusite

Aluminium silicate

Solid density of 3.13 g/cm³

Pouring density of approx. 1.6 g/cm³

Refractoriness: Seger Cone >36

reference temperature: >1800°CLinear expansion α 20 – 600 °C = 6.5

AFS 60 ± 5 | MK 0,23 mm

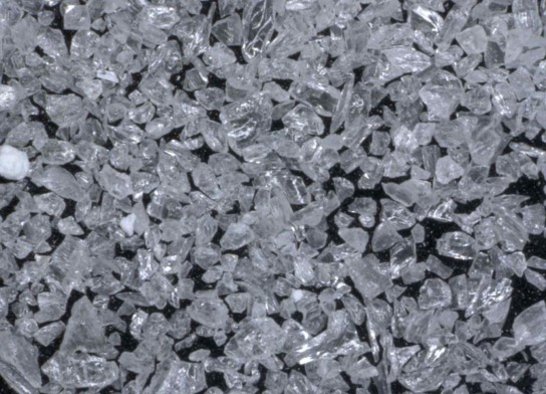

J-Sand

The strengths of J-Sand

- Suitable for all types of castings (except steel casting)

- Special base sand

- Suitable for PUR-Cold-Box, SO2-Cold-Box, shell moulding, resole-CO2 /MF

- 50% lower coefficient of linear expansion than quartz sand

- Optional selection of the ideal classification for your specific applications

Characteristics

- Natural mineral and sand mixture

- Approx. 49 % feldspar + 48 % quartz

Solid density of 2,66 g/cm³

Pouring density of approx. 1,5 g/cm³

Refractoriness: Seger Cone 17

reference temperature: 1500 °CLinear expansion α 20 - 600 °C = 13,7

0,17 / 0,20 / 0,26 / 0,28 / 0,33 (± 0,03 mm)

M-Sand

The strengths of M-Sand

Suitable for all casting types

Suitable for the following processes: PUR-Cold-Box and SO2-Cold-Box, cold resin, resole-CO2 /MF, resole/ester

- Very low coefficient of linear expansion

- Ideally suited for extreme thermal stress

Characteristics

- Melt product = fused mullite

- Aluminosilicate

- Solid density of 3,11 g/cm³

Pouring density of approx. 1,6 g/cm³

Refractoriness: Seger Cone > 36

reference temperature: > 1800 °CLinear expansion α 20 - 600 °C = 4,5

AFS 60 ± 5 | MK = 0,23 (± 0,02 mm)

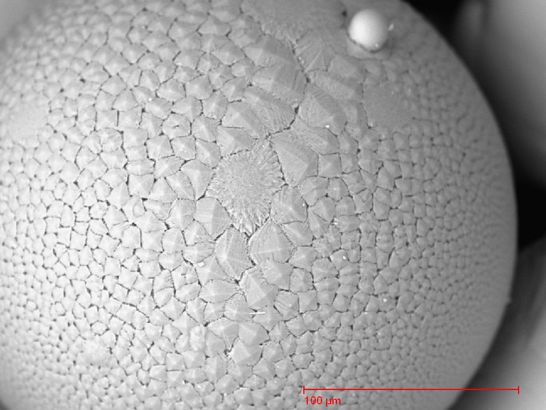

Cerabeads

The strengths of Cerabeads

Suitable for all types of castings

Suitable for the following processes: PUR-Cold-Box, SO2-Cold-Box, shell moulding, cold resin, resole-CO2 /MF, resole/ester

Low coefficient of linear expansion

Ideally suited for extreme thermal stress

- Optional selection of the ideal classification for your specific applications

Characteristics

Synthetischer Synthetic sand = sintered mullite= Sintermullit

Aluminosilicate ( > 80% mullite)

Solid density of 2,86 g/cm³

Pouring density of approx. 1,6 g/cm³

Refractoriness: Seger Cone >36

reference temperature: = 1800 °CLinear expansion α 20 - 600 °C = 4,0

AFS 42, 65 and 107 | MK 0,38 / 0,23 / 0,11 (± 0,02 mm)

Bauxit-Sand

Areas of application

Cold-Box Process | Iron casting

Water jackets for crankcases, cylinder heads, turbines and exhaust manifolds

Cold-Box Process | Al-Casting

Water jackets for crankcases and cylinder heads

Inorganic | Al-Casting

Water jackets for electric drive trains

Characteristics

- Melt product = melt bauxite

≥ 72 % Al2O3 + SiO2, Fe2O3, TiO2

Solid density of 3,3 g/cm³

Pouring density of approx. 2,0 g/cm³

Refractoriness: Seger Cone 36

reference temperature: 1800 °CLinear expansion α 20 - 600 °C = 7,2

AFS 55 ± 5 / 65 ± 5

MK 0,27 / 0,23 (± 0,03 mm)

Foundry characteristics and applications of HA special sands

The main difference between HA special sands and silica sand is the significantly lower coefficient of linear expansion and significantly lower thermal expansion behaviour during the casting process.

Furthermore, HA special sands are the ideal moulding material for core production:

- High sintering and melting points (except J-sand)

- Verträglichkeit mit allen für die Kernfertigung verwendeten Bindemitteln

- High cold-strength properties of the moulding material

- High hot strength properties of the moulding material (except J-sand)

- Available in a range of different classifications

Many years of experience at Hüttenes-Albertus have shown that the use of HA special sands depends on the complexity of the respective casting, the metal used for the casting, the susceptibility to veining, the casting temperature and the binder system.

Application examples

The use of J-sand for PUR Cold-Box core production allows automotive series castings to be produced without sand expansion defects, thereby avoiding the need to add gas and odour-forming additives.

For castings manufactured under extreme thermal stresses with a high tendency to veining, we recommend the use of Kerphalite KF, Cerabeads or M-Sand for PUR-Cold-Box. The high-temperature properties of these HA special sands also ensure that they can be used as a basic moulding material for steel castings.

The thermal expansion of shell moulding material tends towards zero when using quartz-special sand mixtures. When using 100% Kerphalite KF and Cerabeads, shrinkage of the shell core occurs. In sensitive hydraulic and automotive casting, complex cores are produced with coated HA special sands, which guarantee flawless castings close to final dimensions.

Hüttenes-Albertus markets its shell moulding sands containing Cerabeads under the brand name Keracron®.

Your contact