Innovative Feeder Technology

Gargi HA supplies a wide range of state-of-the-art feeder solutions. Technology of feeding solutions is backed by our 100% affiliate Chemex Foundry Solutions GmbH (Chemex for short). Chemex was founded in 1974 and has gone on to become a global technology leader for feeder systems.

Our team is dedicated to collaborating closely with customers to optimise their castings through precisely matched feeder systems, increase output, minimise separation and fettling costs and constantly refine recipes and feeder geometries.

Slurry Sleeves

Gargi HA slurry sleeves are designed to provide effective feeding of metal by extending the solidification time of risers used on Steel, SG Iron, Grey Iron, Copper, Aluminium castings. Whereas exothermic sleeves are designed to initiate an exothermic reaction in the riser thus liberating heat, insulating sleeves provide an efficient thermal insulating layer thereby conserving the heat in the riser over an extended period.

Our sleeves are vacuum moulded and their composition is carefully formulated from high grade insulating / exothermic materials. Also our sleeves are bonded with organic and inorganic binders to provide strong resistant to pressures obtainable during ramming of sand in the foundries. We supply our all types of sleeves in shrink wrapped card board treys which helps to keep them away from moisture and make them suitable for longer time.

Exothermic - Insulative Slurry Sleeves

SF 4000 Sleeves are accurately formed, exothermic and insulating shapes suitable for feeding Iron and steel castings. They are available as open, blind in diameter upto 150 mm. Initial exothermic reaction and insulation afterwards help in increasing the efficiency of sleeve.

Insulative Slurry Sleeves

SF 6000 sleeves are insulating, lightweight riser sleeves used to efficiently feed castings. These sleeves are highly resistant to dilation and provide superior insulating characteristics, with low smoke and fume. The use of riser sleeves increases casting yield by allowing smaller riser sizes than conventional sand risers and reduces cleaning costs.They are available in diameter upto 150 mm.

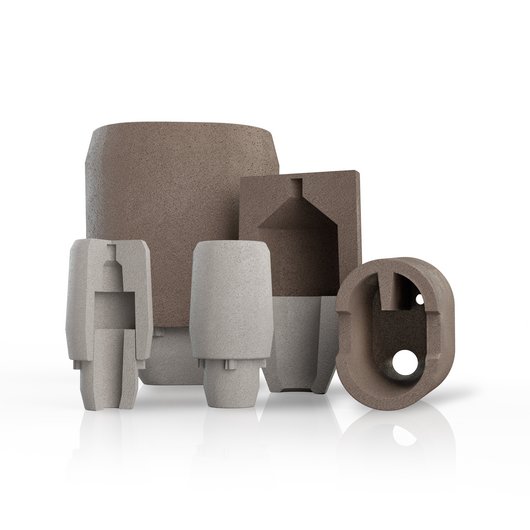

Cold Box Hot Sleeves

An exceptionally broad product portfolio, a comprehensive range of solutions and customized feeding systems for every need: Chemex feeders are the result of intensive research and the application of the latest mechanical and digital technologies.

More information about Cold Box Hot Sleeve

Your contact